If you’re still using bi-metal blades in your reciprocating saw, it’s time to step up to carbide-tipped blades. With three LENOX CT blade options available for the toughest jobs, well…we’ve crunched the numbers. In our opinion, you’re going to save time and money using LENOX carbide tipped reciprocating saw blades.

When you’re cutting metal or mixed materials, carbide-tipped blades give you a major advantage thanks to a blend that’s much tougher than standard bi-metal blades.

Table of contents

Carbide 101

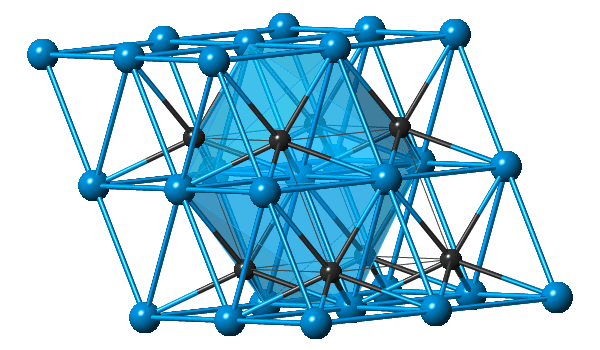

Going back to Chemistry class, the term “carbide” typically refers to a compound that includes carbon and metal. Tungsten carbide is very popular among blades and manufacturers can tweak the metallurgy to get specific blends for each application.

When you’re cutting through tough materials, carbide-tipped blades are faster than bi-metal blades. That’s not to say bi-metal blades are a poor choice—they have their place and can cut very well when you use an optimal speed. The blades are also really inexpensive compared to carbide. But, most guys and gals in the field try to cut everything at full speed and bi-metal simply reaches the end of its life much faster in those situations.

LENOX Carbide Reciprocating Saw Blades Overview

All of the carbide-tipped blades from LENOX start with a tall, thick design. That seems the opposite of what you want for a cordless saw, but it’s actually very beneficial. It makes for a durable blade that resists breaking and wobbling while cutting straight.

These blades feature a unique carbide blend and LENOX makes them in the USA with globally sourced materials. The stiffness of the blades, tooth pitch, and precise TPI for the various “flavors” of the blade makes them extremely effective.

On that last note, one thing LENOX excels at is options. Not content to have a single carbide metal-cutting blade, they give you options for Medium-Thick and Thick Metal. Then you have the DEMOLITION CT solution designed for nail-embedded wood and demo.

LENOX DEMOLITION CT Carbide Tipped Reciprocating Saw Blades

With an aggressive design, LENOX Demolition CT carbide tipped reciprocating saw blades have a 6 TPI tooth count for cutting nail-embedded wood.

Compared to the previous generation of LENOX 6 TPI bi-metal blades, you can expect up to 50 times the blade life when you’re cutting wood with nails.

LENOX LAZER CT Medium-Thick Carbide Tipped Reciprocating Saw Blades

Increasing the tooth count, LENOX has a 10 TPI LAZER CT carbide tipped blade for cutting medium to thick metals. Optimized for 3/16” to 1/2″ metal, these blades also have up to 50 times the life of the LENOX 10 TPI bi-metal blades in cast iron and rebar.

LENOX LAZER CT Thick Metal Recip Blades

Then you have the LENOX LAZER CT carbide thick metal blades. We’ve used these 8 TPI LAZER CT recip saw blades with impressive results on metal over 3/16” thick. Any guesses on the blade life? It’s up to 50 times what you can expect from using a LENOX 10 TPI bi-metal blade on cast iron or rebar.

Pricing and Value

All three carbide-tipped blades are available in 6”, 9”, and 12” lengths, and you can also get the medium metal blade in a 4” length.

Price varies by style, length, and quantity, but let’s take a look at the 9” blades for the sake of comparison. One LENOX DEMOLITION CT nail-embedded wood blade costs $10.99. What about the fifty bi-metal blades it replaces? That would be $145—IF you buy in bulk.

The 8TPI LENOX LAZER CT blade runs $13.99 each and we found the LENOX LAZER CT 10 TPI carbide tipped blades for $23.99. To get 50 of the bi-metal blades that each one replaces will set you back around $135.

With one blade replacing 50, you’re cutting your consumables cost by 80% – 90%, spending less time changing blades, and getting through your cuts faster. The numbers add up, so we say it’s time to make the switch to carbide tipped blades.

I really like the Milwaukee carbide demo blade. Cut through a ton of 3/4 plaster and sheetrock with just one blade